The plant was constructed in several stages:

- Preparatory measures

- Sheet pile sealing wall constructed and maintained until the end of the construction project. 3,700 m² of steel sheet piling in lengths between 14.0 and 15.0 metres was installed as a temporary sealing wall.

- Construction of a sheet piling box using the CSM (Cutter-Soil-Mix) method. The soil was excavated underwater, after which 950 m³ of underwater concrete was placed as the base of the excavation pit.

- Construction dewatering

- Closed dewatering with vertical filter wells, combined with vacuum filter lances including water treatment for transfer to the tunnel stream; geodetic head up to 6.0 metres.

- Civil engineering, engineering and traffic facilities

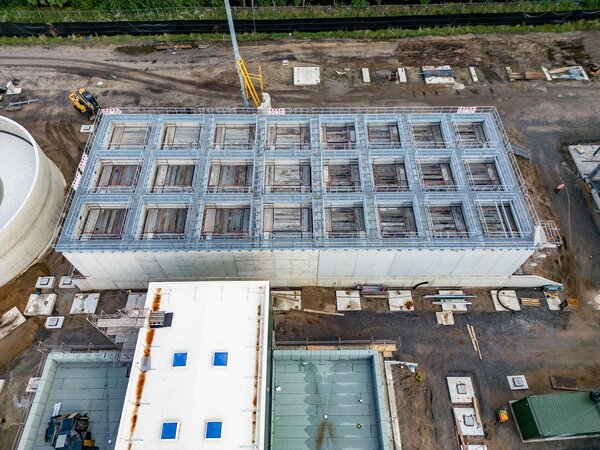

- Neutralisation basin facility with a basin volume of up to 3,600 m³.

- Traffic facilities in asphalt construction including drainage and lighting

- Mechanical and process engineering including pipeline construction and steel construction for

- Feed

- Neutralisation / sedimentation / post-sedimentation

- Demangling / final pH adjustment

- Dewatering

- Control air supply / drinking and process water supply

- Exhaust air technology and unloading area for chemicals

- Electrical and process control technology

- Ensuring the security of supply of the existing plant

- Utilisation and expansion of the existing infrastructure

- Medium-voltage supply / central main energy management / decentralised low-voltage supply

- Automation and process control technology focussing on

- Social building

- Sludge treatment

- Chemical treatment

- Lime milk treatment

- Communication technology

DE

DE

EN

EN